Product category

Product category

Aluminium Circle Manufacturers

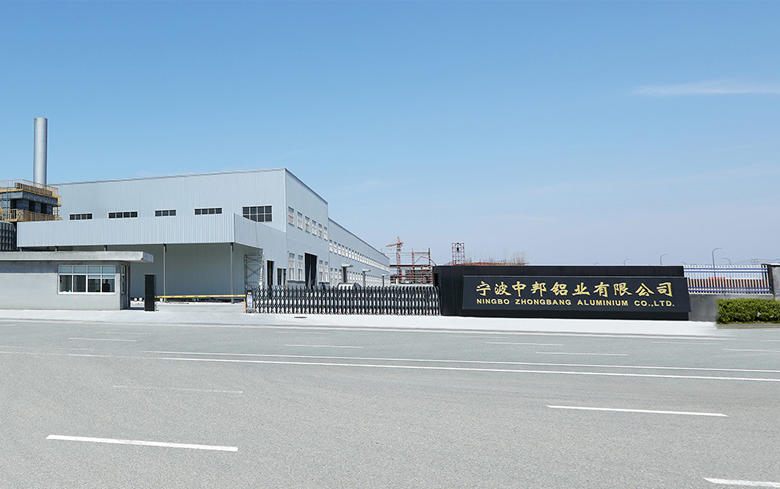

About Zhongbang

Ningbo Zhongbang Aluminium Co., Ltd. is professional China Aluminium Circle Manufacturers and wholesale Aluminium Circle factory.It committed to providing you with reliable quality and service. We specialize in aluminium processing and manufacturing, specializing in various brands of aluminium circles, aluminium ovals, aluminium sheets, aluminium strips and aluminium coils, serving a wide range of aluminium applications, including kitchenware, new energy vehicle battery cases, industrial, building materials and so on. Our Chinese factory is located in Cixi, Ningbo, 30 kilometres from Ningbo port, with extremely convenient trade and shipping conditions.

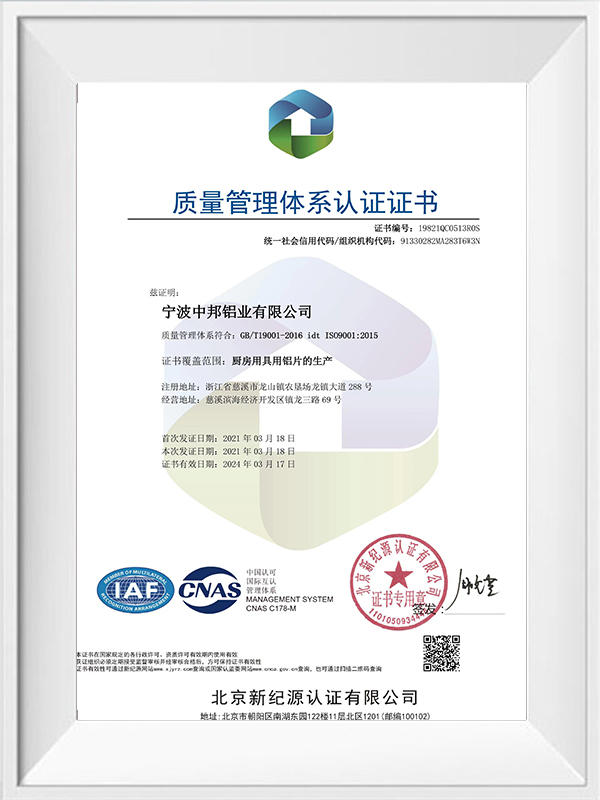

Zhongbang has obtained ISO9001:2015 and TS16949 certifications, and has a good performance in independent innovation. Through unremitting efforts, Zhongbang has become more and more outstanding, daring to break through the established standards in the industry and face the competition head-on.

Zhongbang has always focused on the needs of our customers, and we have strict quality control standards and testing methods to achieve our commitment to quality. Zhongbang Aluminium, the representative of quality and efficiency.

Honor

-

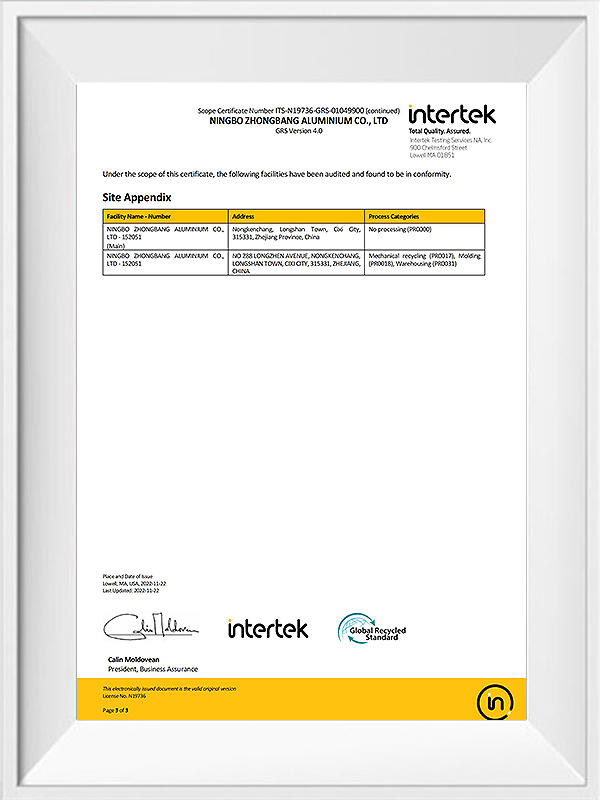

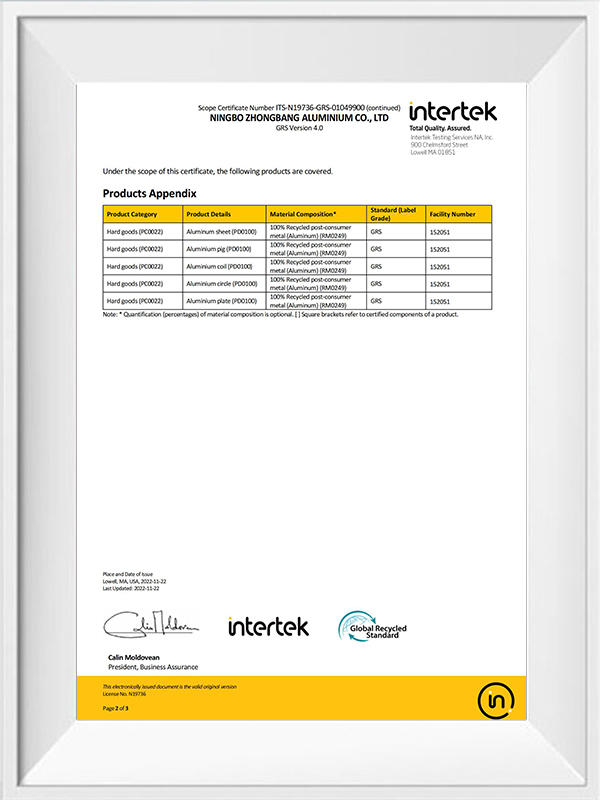

SC-GRS-Certificate

SC-GRS-Certificate -

SC-GRS-Certificate

SC-GRS-Certificate -

SC-GRS-Certificate

SC-GRS-Certificate -

Quality Management System Certification Certificate

Quality Management System Certification Certificate

LATEST NEWS

-

The Versatility of Alloy 4006 Aluminum Circles

2024-11-22

2024-11-22

The Alloy 4006 aluminum circle is available in H22 and O tempers, making it suitable for both deep drawing and spinning applications. With a thickness range of 0.8mm to 9.0mm and diameters spanning 80mm to 1200mm, this aluminum circle provides unparalleled flexibility to meet diverse manufacturing requirements. Its mill finish surface enhances its visual appeal while also ensuring a clean and smooth texture, ideal for applications that require a pristine appearance. 1. Exceptional Strength and Enameling PropertiesAlloy 4006 boasts excellent strength, making it ideal for products that demand durability. Its superior enameling capability ensures a smooth and uniform coating, making it perfect for cookware and decorative items where aesthetics are critical. 2. Wide Range of CustomizationThe aluminum circle supports a variety of disc sizes, including custom shapes and dimensions, offering manufacturers the freedom to design products tailored to specific needs. Whether for large-scale industrial use or niche markets, this flexibility ensures the Alloy 4006 circle fits seamlessly into any production line. 3. Outstanding Reflectivity and Polishing PotentialWith excellent reflectivity, Alloy 4006 is well-suited for applications requiring polished surfaces, such as lighting fixtures and reflective panels. Its adaptability for polishing processes ensures a high-gloss, flawless finish that enhances its visual appeal and functionality. 4. Superior Deep Drawing and Spinning QualityEngineered with precision, this aluminum circle offers exceptional deep drawing and spinning capabilities. The hot-rolled quality ensures fine grains and eliminates looper lines during post-processing, providing a smooth and defect-free final product. 5. Anodizing and Enameling ExcellenceFor applications requiring anodizing, Alloy 4006 delivers high-quality results, including hard anodizing. This makes it a preferred choice for cookware and industrial components that need a robust, long-lasting finish. 6. Clean Surface and Smooth EdgesThe clean, smooth surface of Alloy 4006 circles is a testament to its high production standards. Combined with finely processed edges, it minimizes defects during manufacturing, ensuring a seamless production process and superior end products.Transforming Industries The versatility and performance of Alloy 4006 aluminum circles are transforming multiple industries. In cookware production, their strength and ability to achieve high-quality enameling make them a preferred material for pots, pans, and bakeware. In lighting, their reflectivity and aesthetic finish are ideal for creating elegant fixtures. Meanwhile, their suitability for decorative anodizing unlocks creative opportunities for design-centric applications.

Read More -

1060 Aluminum Circle Gains Popularity in Cookware and Industrial Applications

2024-11-15

2024-11-15

The 1060 aluminum alloy stands out due to its high aluminum content, exceeding 99.6%. This ensures excellent corrosion resistance, thermal conductivity, and lightweight properties, making it ideal for diverse applications. Paired with a range of tempers, including HO, H12, H14, H16, H18, H24, and H26, the material offers flexibility in terms of hardness and strength, allowing manufacturers to tailor it to specific requirements. One of the primary uses of the 1060 aluminum circle is in cookware manufacturing. Its outstanding malleability and ability to withstand deep drawing processes make it suitable for crafting pots, pans, and induction circles. The material's excellent heat distribution ensures uniform cooking, enhancing product quality for end-users. Beyond cookware, the 1060 aluminum circle is also used in decorative items, electrical applications, and industrial components, demonstrating its adaptability across various sectors. Meeting diverse manufacturing needs, the 1060 aluminum circle is available in thicknesses ranging from 0.7 mm to 7.0 mm and diameters between 100 mm and 700 mm. These dimensions cater to both small-scale applications, such as precision components, and larger-scale industrial requirements, such as automotive and aerospace sectors. Recognizing the importance of quality during transit, the 1060 aluminum circles are packaged using robust wooden pallets tailored for exporting. This secure packaging ensures the products arrive in pristine condition, ready for immediate use in production lines worldwide.

Read More -

High-performance 3003 aluminum discs: bringing new quality choices to the kitchenware industry

2024-11-08

2024-11-08

In today's kitchenware market, with the continuous improvement of material performance and product quality requirements, it is particularly important to choose the right metal material. 3003 aluminum discs have gradually become a high-quality material choice in the kitchenware industry with their excellent cold processing forming performance and ductility. This material not only meets the diverse needs of kitchenware, but is also widely used in products such as pot covers, non-stick pans, pressure cookers, hot water kettles, and composite bottoms of induction cookers. It is also favored by the market for its stable quality and excellent cost performance. 3003 aluminum discs are an alloy material with a small amount of manganese added to an aluminum substrate, which has excellent antioxidant and corrosion resistance. Its unique cold processing forming performance makes it perform well in a variety of processing technologies. During the production process, 3003 aluminum discs show good plasticity and ductility, and the elongation can reach 35% to 38%, so that it can meet the needs of various complex structures during shaping and deep drawing. For kitchenware manufacturers, this high ductility can ensure the stability of the product during manufacturing and use, greatly reducing the quality risks caused by material breakage or deformation. From the perspective of usage scenarios, 3003 aluminum discs have brought a variety of application possibilities to the kitchenware industry. When making pot covers, the lightweight characteristics and corrosion resistance of this aluminum alloy can bring consumers a better use experience, which not only reduces the weight of the product, but also effectively extends the service life. Non-stick pans and pressure cookers have higher cooking efficiency due to their good thermal conductivity, while ensuring that the surface of the pot body is not easily damaged. As a composite bottom material for induction cookers, the uniform thermal conductivity of 3003 aluminum discs enables it to heat quickly, which helps save energy and improve cooking results. In short, whether it is household kitchenware or commercial kitchenware, 3003 aluminum discs are an ideal choice that combines functionality and durability. It is worth mentioning that the production process of 3003 aluminum discs is highly environmentally friendly. Due to its good formability, the energy consumption in the manufacturing process is relatively low, and the aluminum alloy material can be recycled many times, which is in line with the current environmental protection concept of sustainable development. The use of this material not only improves product quality and user experience, but also reduces resource waste and contributes to the green transformation of the kitchenware industry.

Read More -

3003 aluminum coil: a versatile choice with both high quality and cost-effectiveness

2024-11-01

2024-11-01

3003 aluminum coil is composed of multiple elements such as aluminum, copper, iron, manganese, silicon and zinc. It combines the advantages of multiple metals and becomes a stable and durable aluminum alloy. Compared with traditional 1100 grade aluminum alloy, the strength of 3003 aluminum coil has increased by 20%, which is mainly due to its fusion with manganese. The addition of manganese not only enhances the strength of the material, but also effectively improves its oxidation resistance and corrosion resistance, so that 3003 aluminum coil can still maintain stable performance in humid and corrosive environments. In addition, 3003 aluminum coil has good formability, and its strength can be further improved by cold working, which meets the different requirements of strength and deformation in different industrial fields. It is precisely because of its excellent corrosion resistance and moderate strength that 3003 aluminum coil is widely used in many fields.In the construction industry, 3003 aluminum coil is often used in building materials such as roof panels, wall curtain walls and ceilings. Its corrosion resistance ensures that it can maintain a long service life when used outdoors. In the automotive industry, this aluminum alloy is widely used in parts such as body panels and fuel tanks. It has good toughness and strength, and can withstand a certain degree of impact without deformation. In the field of food packaging, 3003 aluminum coils are widely used in the production of food containers and beverage cans because they have good insulation against air and moisture, ensuring the freshness and safety of food during the packaging process. In the electronics field, 3003 aluminum coils are widely used in heat dissipation materials for electronic components due to their good conductivity and processability, which can effectively help equipment dissipate heat and extend its service life. As a low-cost, high-performance material, 3003 aluminum coils also have certain advantages in promoting green environmental protection. Aluminum alloy materials can be recycled, which not only reduces resource waste in the production process, but also meets the needs of sustainable development. In addition, 3003 aluminum coils have a very high cost-effectiveness and can meet the needs of large-scale production, especially for cost-sensitive industries such as large-scale construction and mass production of industrial parts. In the international market, the price of 3003 aluminum coils is relatively reasonable, making it the preferred material for many industries, especially small and medium-sized enterprises, which favor its high cost-effectiveness. With the increasing demand for high-performance materials in various industries, the application prospects of 3003 aluminum coils are becoming more and more broad. In the future, 3003 aluminum coils are expected to be promoted on a larger scale in the fields of new energy, aerospace, and home appliance manufacturing. With the continuous advancement of technology, the processing performance and surface treatment process of 3003 aluminum coils will be further improved, opening up more application scenarios for it.

Read More -

8011 Aluminum Circles: The Versatile Solution for Cookware and Beyond

2024-10-25

2024-10-25

In recent years, the demand for innovative materials in the cookware industry has surged, and one such standout option is the 8011 aluminum circle. While typically processed as foils, the disk form of 8011 aluminum presents unique advantages that make it an ideal choice for various applications, particularly in cookware manufacturing. 8011 aluminum circles are notable for their exceptional balance of strength and flexibility. This combination enables manufacturers to produce durable yet lightweight products that can withstand the rigors of everyday use. Whether as bottle caps or heat sink components, the versatility of these aluminum disks extends beyond traditional cookware applications. Their ability to resist corrosion and maintain structural integrity under high temperatures makes them suitable for a range of industrial uses. One of the key advantages of 8011 aluminum circles is their compliance with international standards. The chemical composition adheres to the specifications set forth by Chinese, American, and European aluminum description standards. This ensures that manufacturers can confidently use 8011 aluminum circles in products that require stringent quality controls, meeting consumer expectations for safety and performance. The unique properties of 8011 aluminum circles lend themselves well to various manufacturing processes. They can be easily stamped, cut, and shaped to fit specific design requirements, allowing for a high degree of customization. This flexibility in production is particularly beneficial for OEM and ODM manufacturers looking to create specialized products tailored to their clients' needs. Moreover, the lightweight nature of 8011 aluminum circles contributes to energy efficiency in cooking. Cookware made from these aluminum disks heats up quickly and evenly, reducing cooking times and energy consumption. This not only benefits the environment but also enhances the cooking experience for consumers, who can enjoy faster meal preparation without compromising on quality.

Read More -

Innovative 4006 Aluminum Circles Set New Standards in the Industry

2024-10-18

2024-10-18

In a remarkable advancement for the aluminum manufacturing sector, the introduction of Alloy 4006 aluminum circles has garnered significant attention for its outstanding features and versatile applications. Available in a variety of thicknesses ranging from 0.8mm to 9.0mm and diameters from 80mm to 1200mm, these aluminum circles are set to revolutionize industries that require high-quality aluminum products. One of the key highlights of the 4006 aluminum circle is its temper, available in both H22 and O, which offers excellent enameling properties alongside impressive strength. This unique combination makes it an ideal choice for a wide range of applications, particularly in the cookware and automotive sectors. The aluminum circle's ability to withstand high temperatures while maintaining structural integrity is a testament to its reliability in demanding environments. Moreover, the surface of the 4006 aluminum circle features a mill finish, enhancing its aesthetic appeal and functionality. This surface treatment not only provides a sleek look but also ensures excellent reflectivity, making it an excellent option for polishing. The reflective properties of these circles are especially beneficial in applications such as lighting fixtures, where enhanced brightness and visibility are essential. The flexibility in size is another standout feature of the 4006 aluminum circle. With the capability to produce customized shapes and sizes, manufacturers can meet specific client requirements without compromising on quality. This adaptability is crucial in industries where precision and customization are paramount. Whether for large-scale production or bespoke projects, the 4006 aluminum circle can be tailored to fit various needs. Additionally, the 4006 alloy is recognized for its superior performance in enameling processes, allowing for vibrant and long-lasting finishes. This characteristic makes it a popular choice for manufacturers looking to create visually appealing products that stand the test of time. The ability to achieve a flawless enamel finish on these aluminum circles enhances their marketability and durability. In terms of sustainability, the use of aluminum in manufacturing has proven to be an environmentally friendly choice. Aluminum is 100% recyclable, which aligns with global efforts to reduce waste and promote sustainable practices. By opting for 4006 aluminum circles, businesses not only benefit from high-quality products but also contribute to eco-friendly initiatives. As the demand for high-performance materials continues to grow, the 4006 aluminum circle stands out as a top-tier option for various applications. Its blend of strength, excellent reflectivity, and customization capabilities positions it as a leader in the aluminum industry. Manufacturers and consumers alike can look forward to leveraging the benefits of these innovative aluminum circles in their products.

Read More -

Analysis of the characteristics of 4006 aluminum disc

2024-10-11

2024-10-11

4006 aluminum disc is an aluminum alloy material with excellent performance and has a wide range of applications and excellent processing performance. This alloy material is known for its excellent enamelability, good strength, and good deep drawing and spinning properties, so it is favored in many industrial and manufacturing fields. The following is the detailed characteristics and application analysis of 4006 aluminum discs: The significant advantage of 4006 aluminum alloy is that it exhibits good comprehensive properties in both H22 and O states. The H22 state is a semi-hard state with certain strength and formability, while the O state is a fully annealed state with the highest ductility and toughness, and is suitable for processing processes that require high material plasticity. Therefore, 4006 aluminum discs can provide stable performance whether in applications requiring high strength or in processing processes requiring excellent plasticity. The thickness of 4006 aluminum discs ranges from 0.8mm to 9.0mm, and the diameter ranges from 80mm to 1200mm, which provides users with a wide range of choices. Whether it is a smaller size for fine machining or a large size for heavy equipment manufacturing, this alloy material can meet different needs. In addition, 4006 aluminum discs can be customized in shape and size according to customers' special needs, further enhancing their competitiveness in the production of personalized products. 4006 aluminum alloy discs have excellent glazing properties, which means it bonds well with coating or enamel materials to create a uniform, strong surface. This makes 4006 aluminum discs very popular in applications such as cookware and lamps that require enamel coatings. This excellent glazing performance can also effectively improve the appearance quality and anti-corrosion performance of the product and extend its service life. The aluminum discs feature a "rolled surface" finish that gives the product a pristine, shiny metallic feel, making it excellent in applications requiring high reflectivity. Its excellent reflective properties make it an ideal material for lamp reflectors, optical equipment, decorative panels and other products that require high reflectivity. In addition, the good polishing performance of 4006 aluminum discs also provides a good foundation for subsequent surface treatment. 4006 aluminum alloy shows excellent quality in deep drawing and spinning processes, which can effectively ensure that the material is not prone to cracking, wrinkling or deformation during processing. Therefore, it is often used to manufacture various products that require complex molding processes, such as kitchenware, industrial parts, etc. Due to the material's ductility and workability, it is able to meet molding requirements of different shapes, depths and sizes while maintaining excellent surface quality. Due to its versatility and excellent material properties, 4006 aluminum discs are widely used in many fields. For example, in the household cookware industry, 4006 aluminum discs are used to manufacture pot bottoms, cookware and other products that require high temperature resistance and good thermal conductivity. In the lighting industry, the alloy's high reflectivity and good surface quality make it an important material for lampshades and reflectors. In addition, it is also used in automobiles, electronic equipment, decorative materials and other fields because of its advantages such as durability, formability and beautiful surface.

Read More -

1050 Aluminum Circle is a highly versatile and widely used product in the manufacturing industry

2024-10-04

2024-10-04

1050 Aluminum Circle is a highly versatile and widely used product in the manufacturing industry, particularly for applications that require excellent formability and high corrosion resistance. Composed of 99.5% aluminum, this alloy is classified within the 1000 series of aluminum products, which are known for their superior workability and high thermal and electrical conductivity. These characteristics make 1050 Aluminum Circle an ideal material for deep drawing, spinning, and other shaping processes used in the production of a variety of consumer and industrial goods. The 1050 Aluminum Circle falls under the category of non-heat-treatable alloys. The alloy's high aluminum content, combined with a small percentage of other elements, gives it excellent ductility and malleability. It can be easily formed into various shapes and sizes without cracking or breaking, which is crucial in manufacturing products that require intricate or deep drawing processes. It also possesses excellent reflective properties, making it a suitable material for lighting and decorative applications. In terms of mechanical properties, the alloy offers a moderate level of strength. While it is not as strong as other aluminum alloys, its soft temper (such as HO, H12, H14, H16, H18, H24, and H26) allows it to be easily worked into the desired shape. The tempering process influences the material's hardness and ductility, which can be adjusted to meet specific manufacturing needs. One of the primary applications of 1050 Aluminum Circle is in cookware, especially for deep drawing pots, pans, and induction cooktops. The alloy's excellent heat conduction properties ensure even heating across the surface, making it a preferred choice for manufacturers of high-quality cookware. Additionally, its lightweight nature and non-toxic properties contribute to the production of user-friendly and eco-friendly kitchen products. Beyond cookware, the material is also used in the production of induction circles, reflective equipment, and other industrial parts where high malleability and corrosion resistance are required. It can also be found in the automotive and aerospace industries for producing components that require precision and durability. 1050 Aluminum Circle is available in a wide range of dimensions to suit various applications. The thickness typically ranges from 0.7 mm to 7.0 mm, and the diameter can vary between 100 mm and 650 mm, depending on customer requirements. These flexible specifications make the alloy suitable for a broad range of production processes, from small, intricate components to larger industrial parts. To ensure that the 1050 Aluminum Circle reaches customers in perfect condition, it is securely packed on wooden pallets, designed for easy transportation and protection during shipping. As a China-origin factory specializing in the production of aluminum circles, sheets, and coils, we prioritize the quality of our products and services to meet the diverse needs of our global customers.

Read More -

What is the process of aluminum sheet conducting electricity?

2024-09-27

2024-09-27

Aluminum Sheet is widely used in electronic, electrical and industrial equipment due to its excellent conductivity. Understanding the process of aluminum sheet conducting electricity can help us better utilize the characteristics of this material and ensure high efficiency and reliability in practical applications. The following will discuss in detail the basic principles of aluminum sheet conduction, influencing factors and the conduction process in practical applications. 1. Conductive PrincipleAluminum is a metal material that contains free electrons in its atomic structure. These free electrons can move freely in the metal lattice to conduct current. The conductivity of aluminum is determined by the fewer outer electrons in its atoms and the metal bonding characteristics. When electrons move in the lattice, they can effectively transfer charge.Aluminum has a relatively high conductivity, about 60% of electrical copper. Although aluminum is not as conductive as copper, its lightweight and corrosion resistance make it a preferred material in many applications. 2. Conductive ProcessThe conductive process of aluminum sheet mainly includes the following steps.Voltage application: Apply voltage to both ends of the aluminum sheet to form an electric field. This electric field causes the free electrons in the aluminum sheet to be acted upon and begin to move in the direction of the electric field.Electron migration: When an electric field is applied, free electrons migrate from the negative electrode to the positive electrode. During this process, electrons collide with aluminum atoms, but due to the metallic properties of aluminum, these collisions do not result in significant loss of current.Current flow: As free electrons continue to migrate, current is formed in the aluminum plate. The electrical conductivity of aluminum allows the current to flow smoothly through the material, providing stable power.Heat generation: During the conduction process, a certain amount of heat is generated inside the aluminum plate due to collisions between electrons and atoms. This is the result of part of the electrical energy being converted into thermal energy. The good thermal conductivity of aluminum helps to quickly dissipate this heat and avoid overheating of the material. 3. Factors affecting conductivityThe electrical conductivity of aluminum plates is affected by several factors.Alloy composition: The different alloy compositions of aluminum affect its conductivity. For example, aluminum alloys containing other metal elements (such as manganese, magnesium, etc.) generally have higher strength, but the conductivity may be slightly reduced.Temperature: Temperature has a significant effect on the conductivity of aluminum. Generally speaking, the conductivity of aluminum decreases when the temperature rises, because high temperatures cause atomic vibrations to intensify and electron migration is hindered.Surface treatment: The surface treatment of aluminum sheets (such as oxidation, coating, etc.) will affect their conductivity. Although the oxide film can enhance corrosion resistance, it will reduce conductivity. Therefore, in electrical connections, it is necessary to ensure that the contact surface is clean and free of oxide layer.Thickness and size: The thickness and size of the aluminum sheet will also affect the conductivity. Thicker aluminum sheets have lower resistance, but in some applications, the flexibility and adaptability of thin sheets may be more advantageous. The conductive process of aluminum sheets is a complex and efficient current transmission process, and its basic principles and influencing factors are crucial to practical applications. With the continuous advancement of technology, the conductive properties of aluminum sheets will be further optimized, broadening its application prospects in the electronic and electrical fields. By understanding the conductive mechanism of aluminum sheets, manufacturers and engineers can better utilize this material and improve the performance and reliability of products.

Read More -

What is the forming process of Aluminium Circle 1000 series?

2024-09-20

2024-09-20

The high purity and excellent physical properties of Aluminium Circle 1000 series have been widely used in various industries. Its forming process is a key link to ensure product quality and performance. The forming process of 1000 series aluminum circles will be described in detail below. 1. Raw material preparationThe first step in the forming process is the preparation of raw materials. 1000 series aluminum circles mainly use high-purity aluminum ingots as raw materials. The chemical composition of the aluminum ingots must meet the corresponding standards to ensure that the purity of aluminum reaches more than 99%. The selection of materials is crucial. Suitable raw materials can improve the performance of the finished product and reduce the generation of waste in subsequent processing. In the preparation stage, the aluminum ingots need to be cleaned to remove oxides and impurities on the surface. This process helps to improve the efficiency of subsequent processing and the quality of the finished product. 2. Heat treatmentAfter cleaning, the aluminum ingots usually need to be heat treated. The purpose of heat treatment is to improve the organizational structure of aluminum and make it easier to form in subsequent rolling and stamping processes. The specific temperature and time of heat treatment are adjusted according to the specifications and forming requirements of the aluminum ingot.After heat treatment, the aluminum ingot will soften, so that it can better withstand stress during rolling and stamping, thereby avoiding cracks and deformation. This link is one of the key factors to ensure the quality of aluminum disc forming. 3. RollingAfter the heat treatment is completed, the aluminum ingot enters the rolling process. Rolling is divided into hot rolling and cold rolling. The specific choice depends on the requirements of the finished product and subsequent applications.Hot rolling: rolling at high temperature, mainly used for the initial forming of aluminum ingots. Hot rolling can effectively reduce the yield strength of aluminum, making it easier to shape, and is usually used to make thicker aluminum plates.Cold rolling: rolling at room temperature, used to further thin the aluminum plate and improve its surface quality and mechanical properties. During the cold rolling process, the aluminum sheet will undergo multiple rolling to achieve the required thickness and width.The rolled aluminum sheet is usually cut into the required size by shearing to prepare for subsequent stamping. 4. StampingStamping is the most important step in the forming process of aluminum discs. After rolling, the aluminum sheets will be fed into the stamping machine for punching and cutting to form standard aluminum discs. The stamping process involves multiple steps, including positioning, punching and unloading.Positioning: Before stamping, the aluminum sheets need to be accurately positioned to ensure that the size and shape of each aluminum disc are consistent. The positioning device usually includes a clamp and a guide device.Punching: The aluminum sheet is cut into a circle by applying pressure through the punch of the stamping machine. The speed and pressure of punching need to be adjusted according to the thickness and material of the aluminum sheet to ensure that the cut is smooth and burr-free.Unloading: After stamping, the aluminum discs will be collected by the automatic unloading device for subsequent processing. 5. Surface treatment and inspectionAfter stamping, the aluminum discs usually need to be surface treated, such as cleaning, deoxidation film and coating. This process can improve the appearance quality of the aluminum discs, and also enhance their corrosion resistance and service life.After surface treatment, aluminum discs need to undergo rigorous inspection to ensure that their size, thickness, appearance and other indicators meet the standards. Common inspection methods include visual inspection, measurement and laboratory testing.

Read More -

What factors affect the thermal conductivity of Aluminum Coil?

2024-09-13

2024-09-13

Aluminum Coil is widely used in electronics, aviation, automotive and other industries due to its excellent thermal conductivity. In these applications, good thermal conductivity can ensure the safety and performance of the equipment. However, the thermal conductivity of aluminum coils is affected by a variety of factors, and understanding these factors can help optimize the design and use of the product. 1. Material PurityThe thermal conductivity of aluminum coils is closely related to the purity of its material. The thermal conductivity of high-purity aluminum is better than that of alloy aluminum. The thermal conductivity of pure aluminum is approximately 235 W/(m·K), while the thermal conductivity of alloy aluminum is reduced due to the addition of alloying elements. Impurities in the alloy can interfere with the heat conduction paths between aluminum atoms, resulting in a decrease in thermal conductivity. Therefore, choosing aluminum coils made of high-purity aluminum materials has more advantages in thermal conductivity. 2. Rolling processThe production process of aluminum coils also has a significant impact on its thermal conductivity. During the rolling process, the thickness, temperature and deformation degree of the aluminum coil will affect its microstructure, thereby affecting its thermal conductivity. With a proper rolling process, the grain size in the material can be reduced and the thermal conductivity improved. Heat treatment processes, such as annealing, can also improve the thermal conductivity of aluminum coils, increasing the thermal conductivity by eliminating internal stress and improving the grain structure. 3. MicrostructureThe microstructure of aluminum coils is an important factor affecting thermal conductivity. The size, shape and distribution of grain boundaries of aluminum will all affect thermal conductivity. Smaller grain size generally means better thermal conductivity because heat can be transferred between grains more efficiently. On the contrary, an increase in the number and shape of grain boundaries will lead to an increase in heat conduction paths, thereby reducing thermal conductivity. Therefore, when manufacturing aluminum coils, it is crucial to control their microstructure. 4. TemperatureTemperature also has a direct impact on the thermal conductivity of aluminum coils. The thermal conductivity of aluminum will increase as the temperature increases, but after reaching a certain temperature, the thermal conductivity may become stable. This is because at high temperatures, the atomic motion in aluminum intensifies, allowing it to conduct heat more efficiently. However, excessive temperatures can cause the material's properties to degrade, so its thermal conductivity needs to be carefully evaluated when designing aluminum coils for use in high-temperature environments. 5. Surface treatmentThe surface treatment of the aluminum coil will also affect its thermal conductivity. Although the existence of the surface oxide film can provide excellent corrosion resistance, an excessively thick oxide layer will increase the thermal resistance and reduce the thermal conductivity. To optimize thermal conductivity, modest surface treatments are chosen in many applications to maintain good thermal conductivity while protecting the material. The use of coatings or other materials can increase the durability of aluminum coils without affecting thermal conductivity. 6. Load conditionsIn some applications, aluminum coils may be subjected to different loading conditions, which can affect their thermal conductivity. For example, when a mechanical load or electric current passes through an aluminum coil, it causes an increase in its internal temperature, thereby changing its thermal conductivity. When designing the use scenario of aluminum coils, it is very important to consider the impact of load on thermal conductivity.

Read More -

How to improve the durability and performance of Aluminium Circle through material selection and processing technology optimization when producing automotive parts?

2024-09-06

2024-09-06

In the production of automotive parts, the durability and performance of Aluminium Circle are crucial to the overall performance and safety of the vehicle. As a professional Aluminium Circle manufacturer, we optimize material selection and processing technology to ensure that our products have excellent durability and performance when used in automotive parts. First of all, in terms of material selection, we usually use high-strength aluminum alloy materials for the special needs of automotive parts. These aluminum alloys not only have the inherent lightweight advantages of aluminum, but also improve their strength, hardness and wear resistance by adding other alloying elements (such as silicon, magnesium, copper, etc.). For example, 5-series and 6-series aluminum alloys are often selected for the manufacture of automotive structural and exterior parts due to their excellent mechanical properties and corrosion resistance. In addition, we also further enhance the material's fatigue resistance by controlling the grain size and uniformity of aluminum alloys, which is especially important for automotive parts that require long-term use and are subjected to extreme environmental conditions. In terms of processing technology, we focus on the precise control of process parameters to maximize the performance of aluminum alloy materials. Specifically, during the stamping process of aluminum discs, we strictly control the mold temperature and pressure to ensure the grain fluidity and uniformity of the material during the forming process. After forming, the aluminum discs will undergo precise heat treatment processes, such as solution treatment and aging treatment, to improve their strength and hardness. These processes can not only enhance the mechanical properties of aluminum discs, but also significantly improve their durability, reducing deformation and fatigue damage under high stress and high temperature conditions. In addition, the application of aluminum discs in automotive parts also needs to consider their surface durability. To this end, we will perform a series of surface treatments on aluminum discs, such as anodizing and electrophoretic coating. These treatments can form a dense oxide film or coating on the surface of the aluminum disc, effectively improving its corrosion resistance and wear resistance, thereby extending the service life of the parts. This treatment is particularly important in automotive manufacturing because vehicles are often exposed to humid, salt spray and acidic environments, which are prone to corrosion and performance degradation of metal materials.

Read More

Industry Knowledge Expansion About This Category

2.Diverse Applications of Aluminum Circles