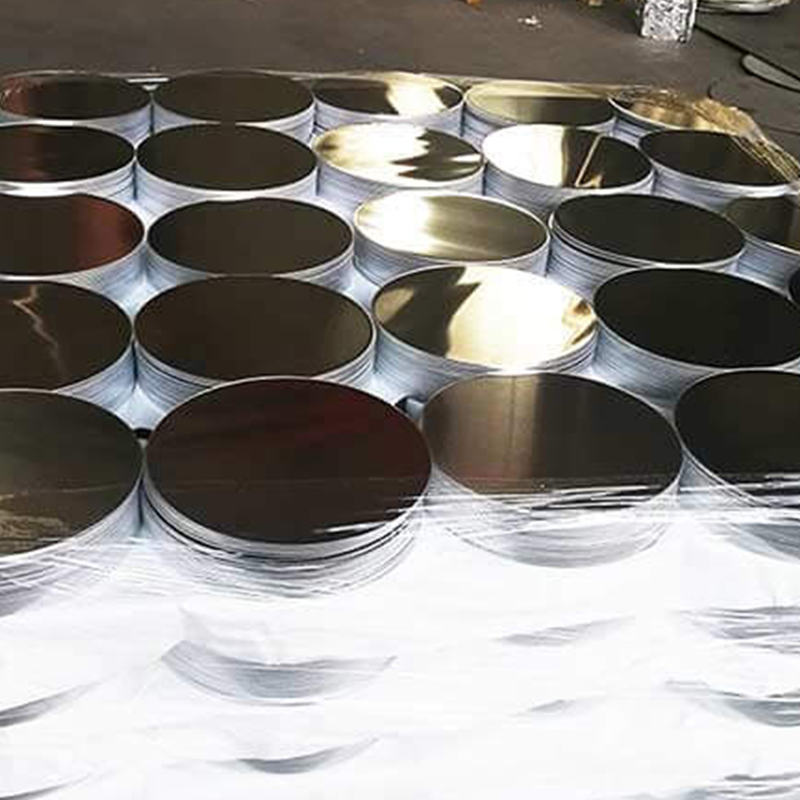

Aluminum circles, sometimes referred to as aluminum discs or aluminum round blanks, are vital components in various industries because of their unique homes. These characteristics, inclusive of lightweight creation, corrosion resistance, and recyclability, have made aluminum a famous desire in manufacturing strategies across the globe.

Aluminum circles are usually made out of aluminum sheet or coil. The production method involves precisely reducing the sheet or coil into circular shapes, resulting in flat discs with uniform thickness. The thickness, diameter, and alloy of the aluminum circle can range relying on the precise requirements of the intended software. Common aluminum alloys utilized in circle manufacturing consist of 1050, 1060, 3003, and 5052, every selected for its specific set of properties and traits.

One of the defining characteristics of aluminum circles is their great corrosion resistance. This assets is because of the formation of a herbal oxide layer at the floor of aluminum whilst exposed to oxygen. This oxide layer acts as a shielding barrier, stopping similarly oxidation and making sure the aluminum remains unfastened from rust and deterioration. This function makes aluminum circles specially appropriate for packages that require exposure to moisture, together with outside signage, boat components, and cookware.

The lightweight nature of aluminum is some other standout feature. Aluminum circles are notably lighter than other metals like metal, while still keeping outstanding energy. This belongings is essential in applications wherein weight loss is important. For instance, in the automobile region, aluminum circles are used within the production of light-weight wheel rims, contributing to progressed gasoline efficiency and overall vehicle overall performance.

Aluminum circles also are recognised for his or her exquisite warmness conductivity, making them a famous preference within the cookware industry. When used in the production of pots, pans, and utensils, they make sure even cooking and temperature manipulate. This is crucial for cooks and home cooks looking to create dishes with regular outcomes. The excessive thermal conductivity of aluminum circles allows for brief and efficient warmness distribution, decreasing hotspots and choppy cooking.

2.Diverse Applications of Aluminum Circles

The versatility of aluminum circles is evident in their huge variety of applications throughout numerous industries.

Cookware: The cookware industry is one of the primary beneficiaries of aluminum circles. They are used to manufacture items along with frying pans, saucepans, and cooking utensils. These circles are perfect for conducting heat evenly, resulting in precise temperature manipulate and most efficient cooking conditions. Aluminum cookware is a staple in kitchens international, ensuring scrumptious food with each use.

Lighting Industry: Aluminum circles play a important position within the lighting fixtures industry, wherein they're used to create lampshades, reflectors, and mild furnishings. Aluminum's exquisite reflective homes make it an excellent desire for correctly directing and diffusing light. Whether it's residential lights, business lights, or commercial lighting fixtures programs, aluminum circles are instrumental in attaining the favored lighting results.

Automotive Sector: The automobile industry blessings from the lightweight and corrosion-resistant residences of aluminum circles. These circles are employed in the manufacturing of numerous additives, which include gas tanks, wheel rims, and ornamental trim. By incorporating aluminum circles into those additives, manufacturers reduce the general weight of motors, contributing to advanced fuel efficiency and handling.

Signage and Nameplates: Aluminum circles are the move-to preference for outdoor applications, together with signage and nameplates. Their corrosion-resistant homes make certain that the finished merchandise can withstand harsh weather situations, UV publicity, and keep a refined look over time. The sturdiness and durability of aluminum circles are critical for signage that desires to face up to the test of time, whether it's for avenue signs, billboards, or business plaques.

Electronics and Electrical Enclosures: The electronics and electrical industries make use of aluminum circles to create enclosures for sensitive digital components and electrical system. These enclosures defend electronics from environmental factors, electromagnetic interference, and physical damage. Aluminum's light-weight and sturdy nature make sure that those enclosures offer dependable protection without including needless weight to the gadget.

3.The Manufacturing Process of Aluminum Circles

The manufacturing manner of

aluminum circles is a particular and complicated procedure that guarantees the production of tremendous, custom-made components for various programs.

Material Selection: The method starts with the cautious choice of the right aluminum alloy and gauge, determined by using the desired homes of the very last product. For example, the selection of alloy might also depend upon elements together with corrosion resistance, formability, or heat conductivity. Common alloys used in aluminum circle manufacturing encompass 1050, 1060, 3003, and 5052.

Blanking: Once the material is chosen, the subsequent step is blanking. Blank circles are reduce from the selected aluminum sheet or coil using specialized system, such as hydraulic or mechanical presses. These machines precisely cut the cloth into round blanks with the desired diameter and thickness. The size and specifications of the blanks range relying at the intended application.

Annealing: After blanking, the aluminum circles may additionally undergo an annealing procedure. Annealing entails heating the circles to a selected temperature after which regularly cooling them. This thermal treatment complements the circles' formability and ductility, making them extra pliable and less difficult to paintings with in the course of next production techniques.

Surface Treatment: Depending on the application, aluminum circles may also go through surface treatments to decorate their appearance and defend towards corrosion. Common surface remedies consist of anodizing and coating. Anodizing creates a long lasting, corrosion-resistant layer at the floor of the aluminum, which may be further dyed or sealed for aesthetic or functional functions. Coating, alternatively, can provide additional safety against corrosion and might encompass non-stick coatings for cookware applications.

Inspection and Quality Control: Quality manipulate measures are an fundamental a part of the manufacturing procedure to ensure that the aluminum circles meet the desired dimensions and high-quality standards. Inspection methods may additionally encompass dimensional exams, visual inspection, and checking out for properties like hardness, floor end, and chemical composition. This rigorous pleasant manipulate guarantees that the completed aluminum circles meet the required standards and are ready for their supposed programs.